There is no doubt that the oil and gas industry is one of the largest pillars in the economy of countries

The rapid development in the industry required a parallel development in the technology of 3D digital modeling, as well as design and drawings.

In the last few years, we noticed the trend of most oil and gas manufacturers to store their products in large farms of storage tanks because of oil barrel price drop.

There was a great need in the market to prepare and produce the fabrication and detailed drawings for a huge number of projects in a record time.

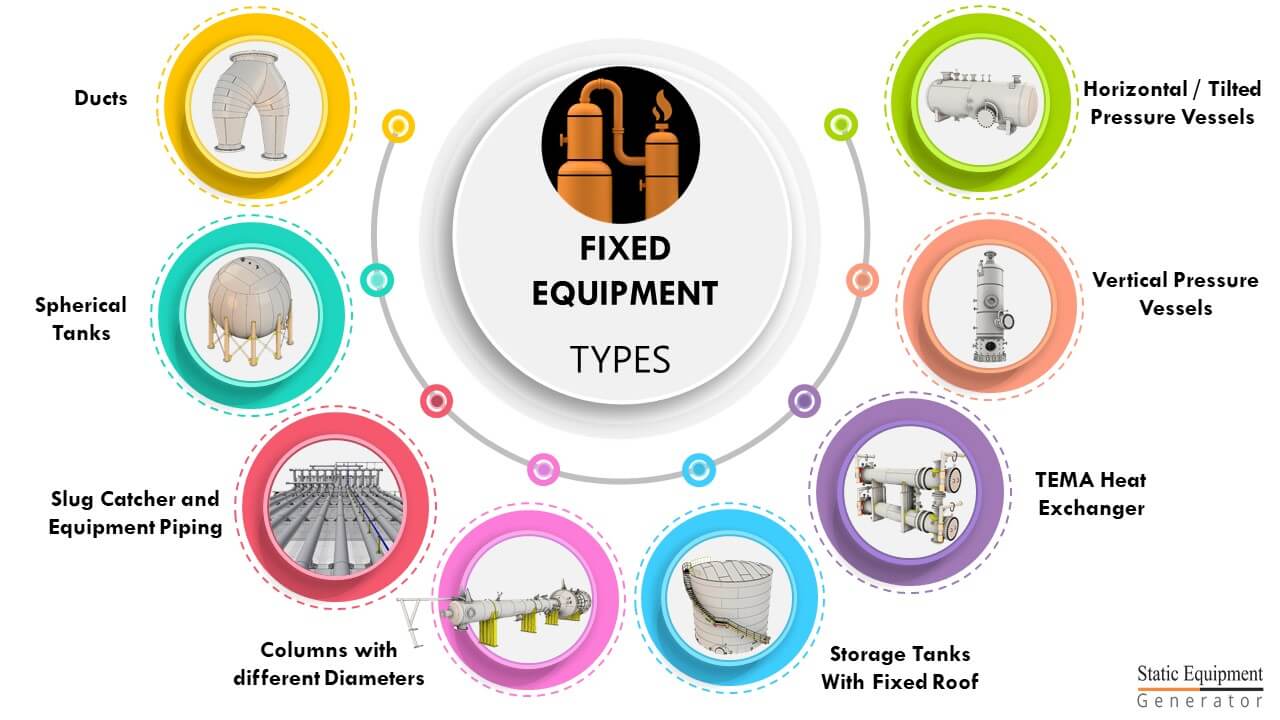

With the continuous increase in the oil and gas production projects, and the need to design and fabricate static Equipment of all kinds (pressure vessels, columns, towers, storage tanks, heat exchanger, Slug catchers, spherical tanks etc.)

Facing that, a noticed lack of keeping pace with the available solutions in the market for this purpose.

At that time, we decided to take a step forward to merge our post studies into our professional work to develop a solution tailored for static Equipment.

We merged our deep knowledge in the computer languages like C# and VBA and our professional mechanical background to create an advanced tool for the accurate and speedy production of 3D digital prototype and workshop drawings.

It was a real challenge for many well-known companies to develop such a software tailored for static equipment but it wasn’t easy at all, the main issue for the developed software was that they weren’t interface friendly or satisfied all the needs for the designers in this business.

From our side we gathered all the needs required by the Draftsmen and designers in this field and we are proud to say that we merge our studies and this market needs to develop a friendly solution being used by well-known fabricators and engineering entities worldwide.

Our solution supports a different configuration and layout of the shell, heads, support structure, nozzles, manways, and other internal as well as external features and appurtenances is facilitated through intuitive menus.

Fabrication details for shell courses, plate sizes, weld types, and other production details are quickly and easily specified.

A complete vessel design can be configured and detailed in less than two hours including the automatic generation of drawings, bill of material, Material Cost Report, and a lot of other reports.